Walton Institute Researcher Leverages Edge Computing and AI to Enable Detection of Milk Adulteration

Tags:

Walton Institute at South East Technological University (SETU) PhD Researcher Rahul Umesh Mhapsekar has carried out research, funded by VistaMilk SFI Research Centre, focusing on ensuring the quality of milk by addressing the issue of adulteration, where substances are added to milk to increase its nutritional value fraudulently.

Adulterants like sulphate, formaldehyde, peroxide, melamine, and caustic acid can be harmful to human health. Traditional lab-based methods for detecting adulteration are time-consuming, leading to delays between detection and product release.

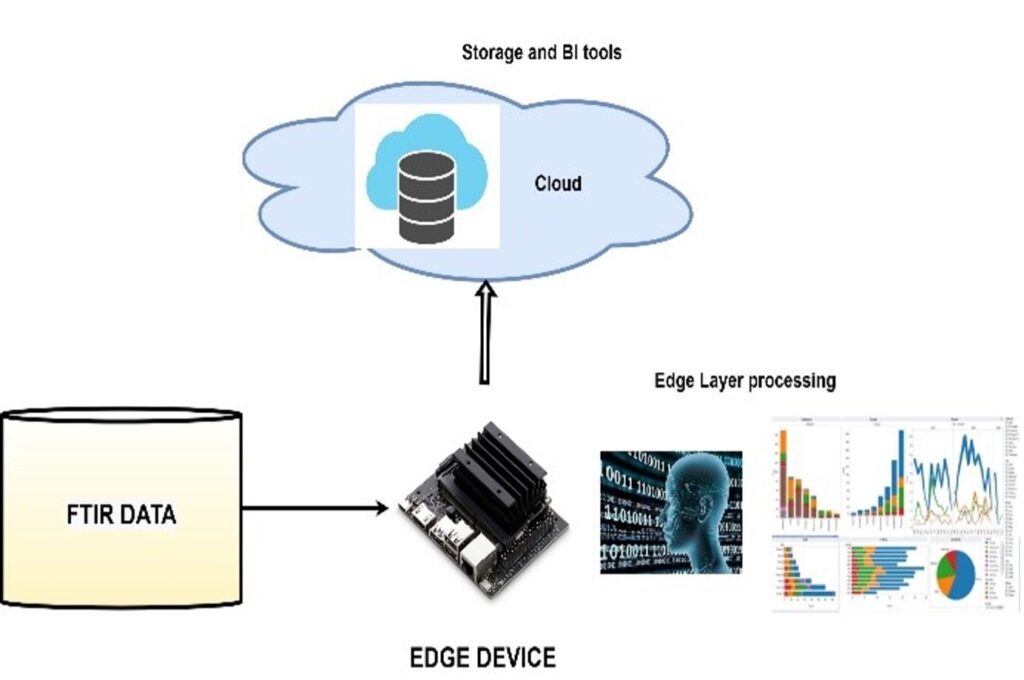

The study proposes the use of edge computing to process data in real-time. An AI algorithm is employed for classification, providing on-site results, and overcoming issues associated with cloud-based solutions, such as delays in the transmission of data for processing, while storing important insights on the cloud for remote visualisations. Rahul has published a paper based on this research, along with Lizy Abraham, Walton Institute Head of Division – ENL; Norah O’ Shea, Teagasc Food Research Centre; and Steven Davy, Technological University Dublin. The paper, published by IEEE is called “Edge-AI Implementation for Milk Adulteration Detection” and can be found here.

Rahul says, “This research has practical implications for ensuring the safety and quality of milk in the food supply chain. By leveraging edge computing and AI, it enables real-time detection of milk adulteration, addressing health concerns associated with harmful substances. This technology could be implemented in dairy farms and plants, providing in-situ milk quality analysis, which is crucial for maintaining high-quality milk in the market. Consumers can benefit from knowing the milk they consume is consistently monitored for adulterants, promoting confidence in the dairy industry.”

The application of this research extends to the dairy industry, particularly in dairy farms and processing plants. Implementing an IoT platform with smart sensors and edge processors for machine learning-based predictive capabilities can revolutionise milk quality analysis. This technology can be integrated into quality control processes, ensuring that only safe and unadulterated milk enters the market. It not only enhances consumer safety but also improves the overall integrity and reputation of the dairy industry.

The next step in this research, Rahul says, is to develop novel AI algorithms which will further improve the prediction accuracy.

This research is funded by VistaMilk SFI Research Centre. For more information on VistaMilk visit www.vistamilk.ie.